Project «Water for Life»

In this part I would like to tell you and show the results of our work done over many years.

The team of the Water for Life project invented, patented and is ready to implement on mass use the innovative desalination technology of saline and brackish waters, as well as of marine, oceanic and underground waters. The technology was invented on the basis of the long-studied but not previously used in this industry sector cavitation effects - SUPERCAVITATION EVAPORATOR.

The main goal of our project:

To develop SUPERCAVITATION EVAPORATORS on the basis of advanced procedure of the calculation of the operating conditions and design parameters taking into account the reduction of the negative effect of the energy systems and facilities on the environment.

The main purposes of the project:

- review of existing assessment methods of process conditions in SUPERCAVITATION EVAPORATORS on the basis of the phenomenological models of the heat-mass-exchange and aerohydrodynamics processes;

- determination of the analytical dependences of the maximum steam production and of hydrodynamic resistance coefficient on operating and structural parameters of the SUPERCAVITATION EVAPORATOR;

- the development of the mathematical model of the heat-mass-exchange and hydrodynamic processes taking into account the steam bleeding. This model will allow to study the elements of energy systems during the projecting phase and during the life cycle;

- the development of the calculation methods for operating and structural parameters of single-stage and multi-stage SUPERCAVITATION EVAPORATORS;

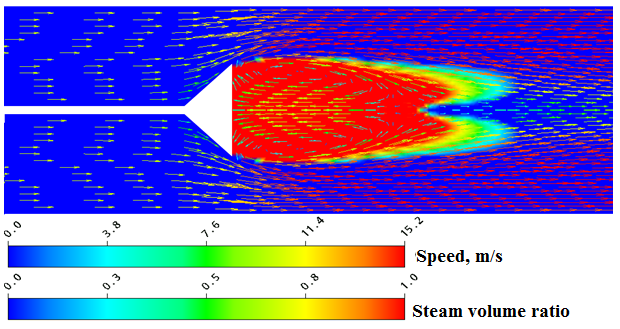

- the numerical computation SUPERCAVITATION EVAPORATORS operating modes on the basis of the developed models. The aim of this is to elaborate recommendations for a designing and an operating of the energy-efficient industrial processes and plants taking into account the reduction of the negative effect of the energy systems and facilities on the environment.

The main results:

- 1. Mathematical models of the heat-mass-exchange and hydrodynamic processes are improved. These models allow assessing the control actions impact (the impurity concentration, the contraction ratio of flow, the quantity of steam bleeding from the cavern, speed, density and temperature of flow) on the processing rate during the projecting phase and during the life cycle. Also they help to improve the calculation accuracy of the process.

- 2. Analytical dependences of the maximum steam production and of hydrodynamic resistance coefficient on operating and structural parameters of the SUPERCAVITATION EVAPORATOR are determined in order to reduce the negative effect of the energy systems and facilities on the environment. Also this allows improving the water conditioning technology.

- 3. The new calculation method of the SUPERCAVITATION EVAPORATOR is offered. This method allows using the mathematic simulation methods during the projecting phase and during the life cycle in order to study the structure and parameters of energy systems as well as to study heat-mass-exchange process in the energy systems. Moreover the sustainable operating and structural parameters of the single-stage and multi-stage SUPERCAVITATION EVAPORATORS are determined.

The researchers of the project «Water for Life» calculated and engineers designed on the basis of the developed mathematical model the acting model of the SUPERCAVITATION EVAPORATOR.

Due to the special stage unit geometric structure of the SUPERCAVITATION EVAPORATOR we managed to get a stable steam generation in the given operating modes with an option to adjust it during the operation.

When solving the problem of steam production, the members of the «Water for Life» project developed and implemented a number of technical solutions that allow obtaining the maximum coefficient of clean water extraction from the total mass of the liquid.

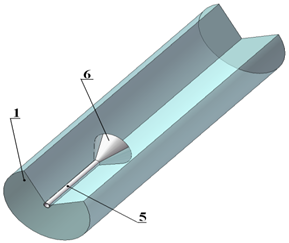

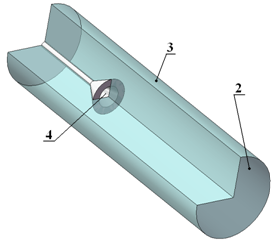

Evaporator`s Stage Unit

- 1, 2 the input and output of the evaporating stage;

- 3 – the inner wall of the SUPERCAVITATION EVAPORATOR`s body;

- 4 – the steam bleeding from the cavern;

- 5- the steam pipe;

- 6- the cavitator.

The factors that determine the evaporation intensity:

- - contraction ratio of flow;

- - the liquid temperature entering the working area;

- - the liquid speed entering the working area;

- - the liquid pressure entering the working area;

- - consumption rate of steam bleeding from the cavern.

Based on the data obtained, we were able to conduct a comparative analysis of the most important indicators in the applied desalination technologies and the SUPERCAVITATIONAL TECHNOLOGY of the EVAPORATOR.

Comparative Analysis

| Cavitational method | Reversed Osmosis | Electrolytic Process | |

| Using of filters | no | yes | no |

| Using of chlorine | no | yes | no |

| Cleaning volume of saline and brackish water | 60-70% | Max 50% | 40-45% |

| Possibility of transportation over long distances | To meet the demand for fresh water consumers located at a distance of up to 400 km from the shore, it is possible to transport water through pipelines. | No, because the prime cost is high, what makes transportation underperforming. | No, because the prime cost is high, what makes transportation underperforming. |

| Water quality | Water treated by the cavitational method based on the Super Cavern meets the highest standards of drinking water. And as a result of many researches conducted by scientists, it was proved that the germination of plants irrigated with water passed through the processing in installations operating according to the cavern principle is 30% higher than that of similar plants irrigated with water from any natural source. | Nowadays this is a controversial issue related to the isotope of H (hydrogen) present in marine and oceanic water. The technology of Reversed Osmosis is not capable of filtering out this isotope in contrast to the installations operating according to the cavern principle or Electrolysis. This drawback is related to the principle of the effect on water flow. The isotope H itself has an extremely negative effect on living organisms and is capable of causing cancer. Not for nothing in the Near East fresh water processed by reversed osmosis is used only for irrigation. | There are no complaints about water quality, so the deep purification process is carried out during the desalination process and the water is suitable not only for irrigation but also for drinking. |

| Ecological Factor | In the process of desalination of marine and oceanic waters, the cavern method has a minimal negative impact on the nature. This is due to the fact that the depth of processing is high enough and allows to efficiently dispose of waste in the form of a relatively small amount of salt solution from which it is possible to extract salt at lower energy costs or, even using tankers, to distribute it in the water mass of the seas and oceans, without harm to the ecosystem. | In the process the ecosystem is irreparably damaged. Desalination forms a large mass of salt solution, which is discharged through the pipelines into the sea or ocean. But since the concentration of salt in the solution is higher than the usual for a particular ecosystem all living organisms within a 2 km radius die. | In the process the ecosystem is irreparably damaged. Desalination forms a large mass of salt solution, which is discharged through the pipelines into the sea or ocean. But since the concentration of salt in the solution is higher than the usual for a particular ecosystem all living organisms within a 2 km radius die. |

| The cost of the complex with the capacity 60 000 m3 a day. Without taking into account the cost of communications and distribution pipelines |

30 million $ | 35 million $ | 50 million $ |

Scientists from over the globe have the same opinion that water consumption will increase because of the following factors:

- - the growth of population;

- - the global warming;

- - the growth of agricultural areas;

The share of existing desalination technologies in this industry will decrease because of the increasing water prime cost. They will be replaced by new technologies which do not have so many disadvantages.